The Australian industrial environment is radically changing in the manner it handles environmental hazards in 2026. The conventional oil spill kit used over decades had virtually rested on polypropylene (PP) pads, which are petroleum-based synthetics; which, although useful, have now become a liability in a time of rigid ESG (Environmental, Social, and Governance) requirements.

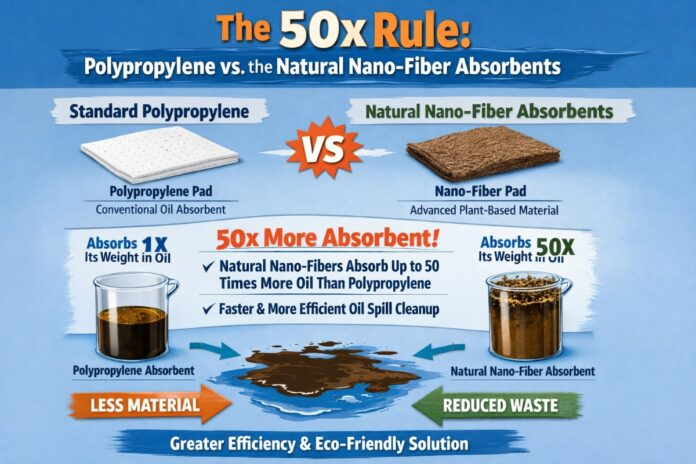

The introduction of the 50x Rule has practically marked the termination of the PP age and gave way to natural nano-fiber technology which has better performance and a much lower environmental impact.

The Science of the 50x Rule: The Synthetic Limits Beyond Synthetic Limits

The absorption capacity of nano-treated natural fibers is called the 50x Rule. Whereas conventional polypropylene pads usually catch 10-20 times their own weight in hydrocarbons, the recent natural nano-fibers, based on cotton, kapok, and biomass, can catch 50 litres of pure oil per kilogram of the product.

The immense increase in efficiency has been the result of the high porosity and altered surface chemistry of the fibers. Using nanotechnology to increase the natural oleophilicity (oil-attraction) and hydrophobicity (water-repulsion) of these plant-based substances, manufacturers have developed an absorbent which feeds on oil without becoming submerged in any way, even on the turbulent waters of an oil spill kit in a Bass Strait.

The Reason your Current Oil Spill Kit is Probably Outdated

To most Australian safety officers, the move towards nano-fiber is not merely guided by absorption ratio; this is the requirement of the new 2026 WHS (Work Health and Safety) and the EPA compliance requirements.

1. Lower Waste and Disposal Charges

Due to the high efficiency of natural nano-fibers, the amount of material you need to deal with the same spill is considerably reduced. This means smaller, more mobile kits and a huge decrease in the quantity of the “Regulated Waste” which needs to be carried and disposed. A large country such as Australia stands to benefit instant bottom-line the reduction of the logistics of the waste disposal.

2. Superior Oil Retention

One side effect of older PP pads is the leakage out of the pad as the oil drips back during transit, this is known as leaking. The nano-fibers rely on a capillary action at molecular level to trap the oil inside the fiber lumen so that when the oil is trapped, it remains trapped.

Future-Proofing Australian Workplaces

By 2026, you will not only visit the store and say what you want in your oil spill kits, but rather the price per pad is not the only criterion any more but is also efficiency, compliance and sustainability. The natural nano-fiber absorbents do not only match the existing standards, they actually surpass them by offering 50x the strength besides a fraction of the effects on the environment. The Australian industry that wants to become the best in safety and sustainability, the replacement of polypropylene with nano-fiber is not just an upgrade, but a must have.