Moisture damage remains one of the most persistent challenges in UK homes and commercial properties, particularly in bathrooms, kitchens, and below-ground spaces where damp conditions are common.

Traditional wall finishes such as paint and plaster can deteriorate rapidly when exposed to prolonged humidity, leading to mould growth, structural damage, and costly repairs. 3D PVC wall panels have emerged as a practical solution for these environments, offering a combination of water resistance, durability, and design flexibility that addresses the specific demands of moisture-prone areas in British properties.

This guide examines the key benefits of using 3D PVC wall panels in damp conditions, with particular focus on applications relevant to UK homeowners, landlords, and commercial property managers.

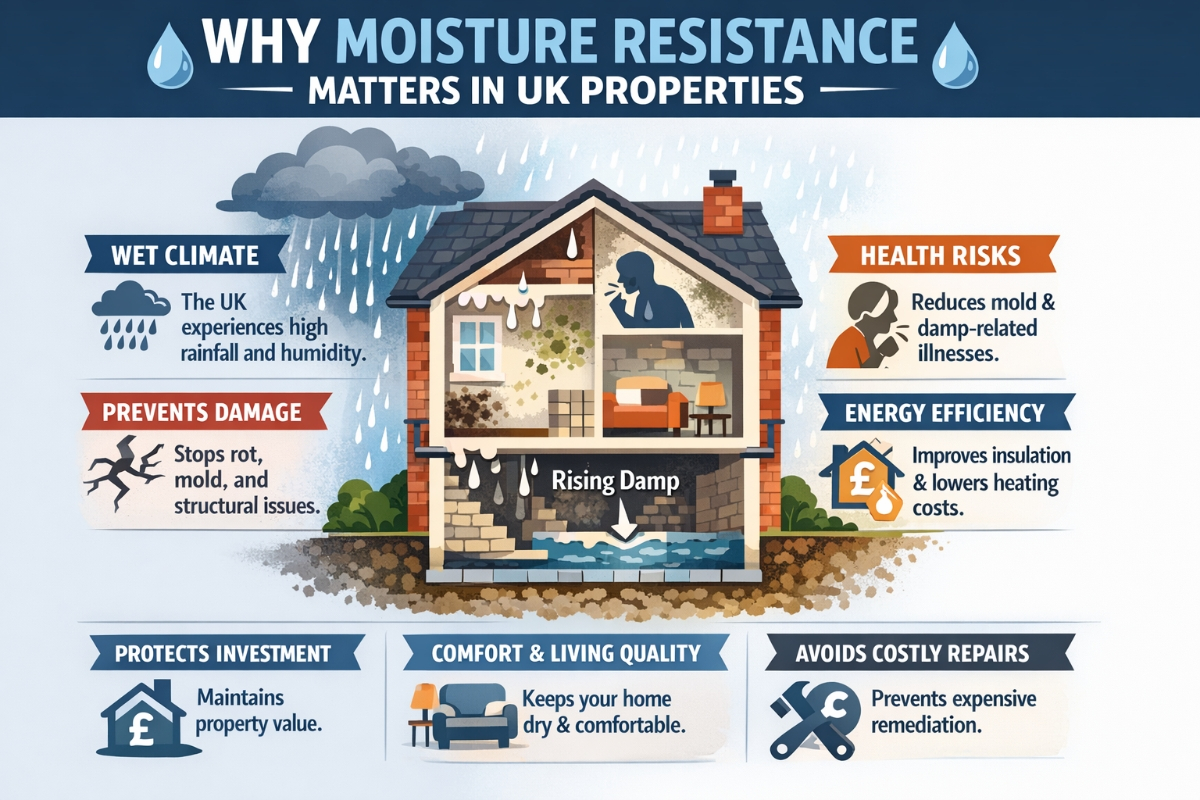

Why Moisture Resistance Matters in UK Properties

The UK’s temperate maritime climate creates consistently high humidity levels throughout much of the year. Properties in coastal regions, areas with high rainfall, and older buildings with limited ventilation are especially susceptible to moisture-related problems.

Bathrooms, utility rooms, and kitchens experience daily exposure to steam and water splashes, whilst basements and ground-floor spaces may contend with rising damp or condensation issues.

Waterproof wall panels provide a protective barrier that prevents water penetration into underlying wall structures. Unlike paint or wallpaper, which can peel or bubble when exposed to moisture, PVC panels maintain their integrity in consistently humid conditions, making them particularly suitable for British properties where damp is an ongoing concern.

Superior Water Resistance and Protection

3D PVC wall panels are manufactured from polyvinyl chloride, a non-porous material that repels water rather than absorbing it. This fundamental property makes them substantially more effective than traditional wall finishes in preventing moisture damage.

The panels form a continuous protective surface when properly installed, with sealed joints that prevent water from reaching the substrate behind. This is particularly valuable in shower enclosures, around baths, and in areas where splashing occurs regularly. Unlike ceramic tiles, which rely on grout lines that can deteriorate and allow water ingress, moisture-resistant wall panels create a more reliable barrier with fewer vulnerable points.

In UK bathrooms where ventilation may be limited—common in period properties and flats—these panels help protect wall structures from the cumulative effects of steam and condensation. The material does not support mould growth on its surface, addressing a significant health and maintenance concern in British homes.

Durability and Longevity in Damp Environments

The lifespan of interior wall cladding in moisture-prone areas depends largely on its ability to withstand repeated exposure to water, temperature fluctuations, and cleaning agents. PVC wall panels demonstrate considerable durability in these conditions.

The material resists warping, swelling, and degradation that typically affect moisture-sensitive finishes. In kitchens where steam from cooking combines with grease and food splashes, the panels maintain their structural integrity and appearance. Commercial wash areas, changing rooms, and restaurant kitchens benefit from this durability, as the panels withstand intensive daily use without requiring frequent replacement.

British rental properties present particular challenges due to high turnover and varied maintenance standards. Bathroom wall panels in these settings can endure years of use with minimal deterioration, reducing the frequency of refurbishment between tenancies and lowering long-term costs for landlords.

How Do 3D PVC Wall Panels Compare to Ceramic Tiles?

The comparison between PVC panels and ceramic tiles is relevant for anyone planning bathroom or kitchen renovations in the UK. Both materials offer water resistance, but they differ significantly in installation, maintenance, and long-term performance.

Ceramic tiles require professional installation, extensive substrate preparation, and skilled grouting work. The installation process is time-consuming and generates considerable dust and disruption. Grout lines, whilst initially sealed, become vulnerable to water penetration over time, requiring periodic resealing and eventual replacement.

3D PVC wall panels can be installed more quickly, often directly onto existing surfaces if they are sound and level. The reduced installation time translates to lower labour costs—a significant consideration for UK property owners managing renovation budgets. The absence of grout lines eliminates a major maintenance requirement and reduces the risk of water damage to underlying structures.

Tiles remain susceptible to cracking from impact, particularly in busy households or commercial settings. PVC panels demonstrate greater resilience to knocks and impacts, making them practical for family bathrooms and high-traffic commercial washrooms.

Ease of Installation for UK Renovation Projects

The installation process for waterproof wall panels is considerably more straightforward than traditional tiling, making them accessible to competent DIY enthusiasts as well as professional installers. This has particular relevance in the UK property market, where renovation costs frequently exceed initial estimates.

Panels typically measure between 2.4 and 2.7 metres in length, allowing for floor-to-ceiling coverage with minimal joints. They can be cut to size using standard woodworking tools, fitted around obstacles such as pipework and electrical fittings, and secured using adhesive or mechanical fixings depending on the substrate.

The lightweight nature of PVC panels compared to ceramic tiles reduces structural load—an important consideration in older British properties where floor and wall structures may have limited load-bearing capacity. Loft conversions, upper-floor bathrooms, and rooms with stud partition walls can be fitted with PVC panels without concern for excessive weight.

Installation disruption is substantially reduced compared to tiling projects. A typical bathroom can be clad in a day or two rather than the week or more required for tiling, grouting, and drying. For rental properties requiring quick turnaround between tenancies, this time saving is particularly valuable.

Low Maintenance Requirements

Ongoing maintenance requirements directly affect the total cost of ownership for any wall finish. 3D PVC wall panels require minimal maintenance compared to alternative moisture-resistant materials.

The smooth, non-porous surface resists dirt accumulation and can be cleaned using standard household cleaning products. Unlike painted surfaces that require periodic repainting, or tiles that need grout maintenance, PVC panels retain their appearance with simple wiping down. This is particularly relevant in commercial kitchens, care homes, and other settings where hygiene standards are paramount and cleaning occurs multiple times daily.

The panels do not harbour bacteria or mould on their surface, provided they are properly installed and adequate ventilation is maintained. This contributes to healthier indoor environments in bathrooms and kitchens—spaces where air quality can be compromised by biological growth on moisture-retaining surfaces.

British hard water, which leaves limescale deposits on bathroom surfaces in many regions, can be easily removed from PVC panels without damaging the finish. Tiles and natural stone surfaces often show permanent staining or dulling from repeated limescale exposure.

Design Versatility for Modern UK Interiors

Contemporary 3D PVC wall panels are available in an extensive range of finishes, textures, and colours that align with current UK interior design trends. The three-dimensional surface patterns add visual interest and depth to walls, moving beyond the flat appearance of traditional waterproof materials.

Available finishes include realistic stone effects, wood grain patterns, abstract geometric designs, and plain colours. This variety allows property owners to achieve specific aesthetic goals whilst maintaining the practical benefits of moisture resistance. Bathroom wall panels can complement contemporary, traditional, or minimalist design schemes without compromise.

The textured surface of 3D panels can help disguise minor imperfections in underlying walls, particularly useful in older British properties where walls may not be perfectly flat. This reduces the preparatory work required before installation compared to tiles, which demand very flat, even substrates.

For rental properties and commercial spaces, neutral designs in light colours help create bright, clean environments that appeal to a broad range of tastes. The ability to achieve high-end aesthetics at moderate cost makes PVC panels attractive for budget-conscious renovation projects.

Cost-Effectiveness for UK Property Owners

The total cost of wall finishes must account for materials, installation labour, disruption, and long-term maintenance. When these factors are considered comprehensively, moisture-resistant wall panels often represent better value than traditional alternatives.

Material costs for mid-range 3D PVC panels are comparable to good-quality ceramic tiles. However, installation costs are typically lower due to reduced labour time and the possibility of DIY installation. Professional installation rates in the UK vary by region, but the simpler installation process for panels generally results in lower overall project costs.

The elimination of grout maintenance, reduced need for redecoration, and extended lifespan in moisture-prone conditions contribute to lower long-term costs. For landlords managing multiple properties, the reduced maintenance burden and longer intervals between refurbishments improve return on investment.

In commercial settings such as restaurant kitchens, changing facilities, and healthcare environments, the ability to install panels during short closure periods minimises lost trading time or service disruption—an often-overlooked economic benefit.

Suitability for UK Climate Conditions

Britain’s climate presents specific challenges for building materials, with high ambient humidity, frequent temperature fluctuations, and limited natural light in many properties. Interior wall cladding materials must perform reliably under these conditions year-round.

3D PVC wall panels maintain dimensional stability across the temperature ranges experienced in heated British properties. They do not expand or contract significantly with temperature changes, preventing the cracking or separation that can affect some materials. This stability is particularly important around heated towel rails, radiators, and other heat sources commonly found in UK bathrooms.

The panels perform effectively in unheated or intermittently heated spaces such as utility rooms, garages converted to living space, and holiday properties that may be vacant during winter months. Traditional paint and plaster finishes in these environments often suffer from condensation damage and mould growth during cold periods.

Basements and below-ground rooms in British properties frequently experience persistent dampness. Whilst proper damp-proofing remains essential, waterproof wall panels provide an additional protective layer that helps manage moisture and maintain a usable interior surface even in challenging conditions.

Applications in UK Commercial Properties

Commercial properties face more demanding conditions than residential spaces, with higher usage intensity, stricter hygiene requirements, and greater scrutiny of maintenance costs. 3D PVC wall panels address several practical concerns in these environments.

Restaurant and café kitchens require surfaces that withstand heat, moisture, grease, and frequent cleaning with commercial-grade products. PVC panels meet these demands whilst offering easier installation than stainless steel cladding and better moisture resistance than painted surfaces.

Changing rooms in gyms, sports facilities, and swimming pools experience constant moisture exposure combined with high traffic. The durability and water resistance of PVC panels make them suitable for these applications, whilst their design versatility allows facilities to maintain attractive interiors.

Care homes and healthcare facilities require surfaces that support infection control protocols. The non-porous, easily cleanable surface of moisture-resistant wall panels contributes to maintaining hygienic environments whilst withstanding the rigours of professional cleaning regimens.

Student accommodation and hotels benefit from the panels‘ resistance to damage and ease of maintenance. The reduced need for repairs and redecoration between occupancies improves operational efficiency.

Are 3D PVC Wall Panels Environmentally Responsible?

Environmental considerations increasingly influence material choices in UK construction and renovation. PVC panels present a mixed environmental profile that merits balanced consideration.

The durability and longevity of PVC panels means they require less frequent replacement than some alternative materials, reducing resource consumption over the building’s lifetime. Their lightweight nature reduces transportation emissions compared to heavier materials such as tiles.

PVC manufacturing has environmental impacts, as does end-of-life disposal. However, many manufacturers now offer panels with recycled PVC content, and the material is theoretically recyclable, though collection and recycling infrastructure in the UK remains limited.

For property owners prioritising environmental concerns, selecting panels from manufacturers with environmental certifications, opting for products with recycled content, and ensuring proper end-of-life disposal through appropriate channels can mitigate some environmental impacts.

Compliance Considerations for UK Properties

Building regulations and material standards ensure that construction materials meet safety and performance requirements. 3D PVC wall panels intended for use in UK properties should comply with relevant standards.

For fire safety, panels should meet appropriate classifications. In domestic properties, materials should comply with requirements for surface spread of flame. Commercial and public buildings have more stringent requirements, and panels used in these settings must meet the appropriate fire performance standards.

Reputable suppliers provide technical data sheets confirming compliance with relevant British and European standards. Property owners should verify that products meet requirements before purchase, particularly for commercial installations where regulatory compliance is more strictly enforced.

Whilst PVC panels themselves provide water resistance, they do not replace proper waterproofing measures required by building regulations. Tanking systems, damp-proof courses, and adequate ventilation remain necessary components of moisture management in UK properties.

Frequently Asked Questions

What are 3D PVC wall panels used for in moisture-prone areas?

3D PVC wall panels provide waterproof wall cladding for bathrooms, shower enclosures, kitchens, utility rooms, and other spaces exposed to moisture. They protect underlying wall structures from water damage whilst offering a decorative finish. Common applications include residential bathrooms, rental property refurbishments, commercial kitchens, and changing facilities.

Are 3D PVC wall panels suitable for UK bathrooms and kitchens?

Yes, 3D PVC wall panels are highly suitable for UK bathrooms and kitchens. They resist moisture, steam, and splashing effectively, whilst withstanding the humidity levels common in British properties. Their water resistance makes them particularly practical for shower areas, around baths, and behind sinks where ceramic tiles have traditionally been used.

How do 3D PVC wall panels compare to tiles in damp conditions?

Both materials offer water resistance, but PVC panels install more quickly, require less substrate preparation, and eliminate grout lines that can allow water penetration. Panels are more impact-resistant than ceramic tiles and require minimal maintenance. Tiles offer a more traditional aesthetic and greater heat resistance but involve higher installation costs and more complex maintenance requirements.

Are 3D PVC wall panels compliant with UK interior standards?

Quality 3D PVC wall panels from reputable manufacturers comply with relevant British and European standards for interior wall cladding. For domestic use, panels should meet surface spread of flame requirements. Commercial installations require verification that panels meet appropriate fire performance classifications. Property owners should request technical data sheets confirming compliance before purchase.

How long do 3D PVC wall panels last in humid environments?

Properly installed 3D PVC wall panels typically last 15-20 years or more in humid environments, depending on usage intensity and maintenance. The material does not degrade from moisture exposure and maintains its appearance with basic cleaning. In commercial settings with intensive use, lifespan may be shorter but still exceeds many alternative wall finishes. Regular cleaning and adequate ventilation help maximise longevity.

Content Transparency Notice

This article was created with the assistance of AI technology and has been carefully reviewed, edited, and verified by our editorial team to ensure accuracy, relevance, and value for our readers. We use AI as a tool to enhance our content creation process while maintaining high standards of quality and originality. All information provided has been fact-checked and reflects our commitment to delivering helpful, trustworthy content. If you notice any errors or have suggestions for improvement, please feel free to contact us.